Elevator geared traction YJ240B

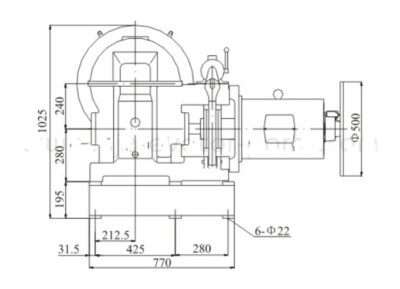

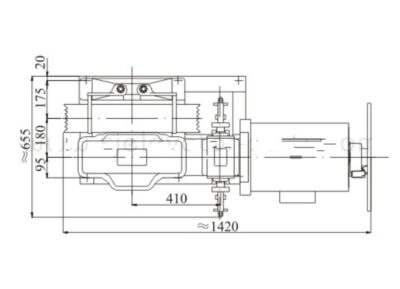

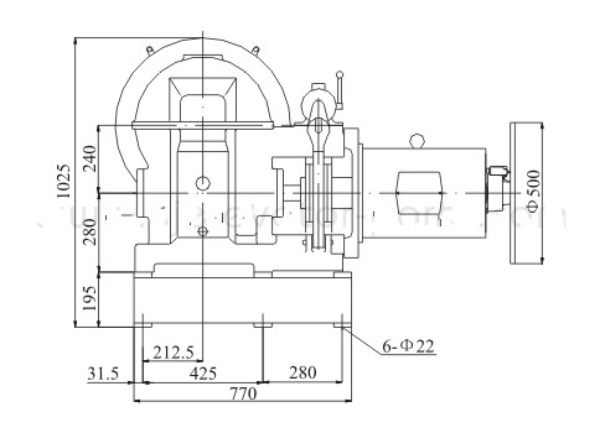

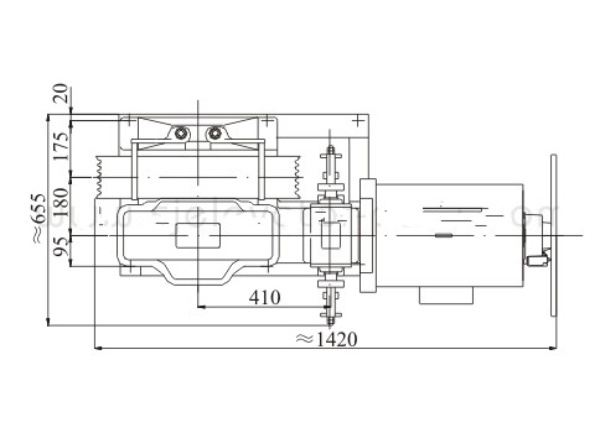

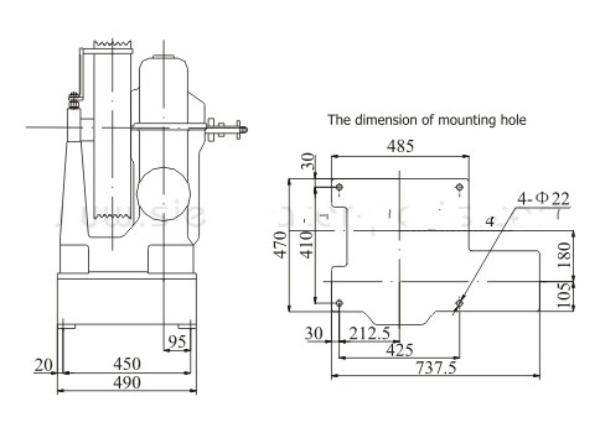

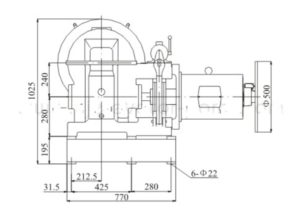

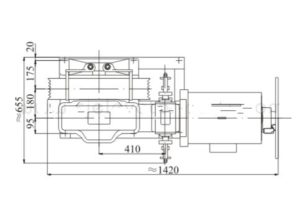

Elevator geared traction machine YJ240B

Model:YJ240B

Brand:General

MOQ:1 pcs

Warranty Time:1 year

Certificates:ISO9001

Elevator geared traction machine YJ240B

I.Max. Static Load: 7500 kg

II.Control: VVVF

III.Brake: DC110V、2A

IV.Weight(with support): 730kg…

- Description

Description

Elevator geared traction machine YJ240B

Technical Parameters

Elevator geared traction machine

|

Load(kg)

|

LiftSpeed(m/s) | Ratio | Sheave Diam(mm) | Rope sheave(mm) | Motor Power(kW) | Pole |

| 800 | 1.6 | 59:2 | φ620 | 5Xφ13X20 | 12.5 | 4 |

| 800 | 1.75 | 55:2 | φ620 | 5Xφ13X20 | 15 | 4 |

| 800 | 2 | 49:2 | φ620 | 6Xφ13X20 | 18.5 | 4 |

| 1000 | 1 | 49:1 | φ620 | 5Xφ13X20 | 11 | 4 |

| 1000 | 1.6 | 59:2 | φ620 | 6Xφ13X20 | 18.5 | 4 |

| 1000 | 1.75 | 55:2 | φ620 | 6Xφ13X20 | 18.5 | 4 |

| 1000 | 2 | 49:2 | φ620 | 6Xφ13X20 | 18.5 | 4 |

| 1150 | 1 | 49:1 | φ620 | 6Xφ13X20 | 15 | 4 |

| 1150 | 1.6 | 59:2. | φ620 | 6Xφ13X20 | 18.5 | 4 |

| 1150 | 1.75 | 55:2 | φ620 | 6Xφ13X20 | 18.5 | 4 |

| 1150 | 2 | 49:2 | φ620 | 6Xφ13X20 | 22 | 4 |

What is the difference between geared and gearless elevators?

Gear-less traction elevators have a high initial cost, medium ongoing maintenance costs, and use energy a bit more efficiently than geared traction elevators.

2.Geared traction elevators are capable of travel speeds up to 500 feet per minute. The maximum travel distance for a geared traction elevator is around 250 feet.

Gear-less Traction Elevators have the wheel attached directly to the motor. Gear-less traction elevators are capable of speeds up to 2,000 feet per minute and they have a maximum travel distance of around 2,000 feet so they are the only choice for high-rise applications.

Elevator geared traction machine Advantages

— No risk of oil contamination in the ground and offers almost unlimited travel.

—Geared traction car speeds are typically much faster than hydraulic applications, can move at 500 (fpm) (2.5 m/s) or less

—Better acceleration and deceleration rates than hydraulic, better floor to floor performance times.

—A wide range of capacities are available, accommodate low capacity passenger cars and high capacity freight cars.

—Because of the counterweight arrangement, power efficiency is greater than that of a hydraulic application.

—The geared traction equipment type is less expensive than the gearless traction type.

—Geared traction has a freight payload; the MRL equipment type has no freight payload.

Elevator geared traction machine Disadvantages

— The material cost and the installation time are substantially higher when compared to any of the hydraulic applications.

— There are structural building considerations, since all of the loading forces are hanging from the overhead.

— Elevator maintenance cost is generally higher (compared to hydraulic elevators).

— The time it takes to deliver and install the geared traction elevator after sending the purchase order is longer than for the hydraulic elevator type.

— Geared traction requires a larger machine room than the control room required by MRL traction equipment type.

— Geared traction has lower speeds than gearless traction equipment types