Heidenhain elevator encoder ERN1387

Heidenhain elevator encoder ERN1387 204862S14-70

Model:ERN1387 204862S14-70

Brand:Heidenhain

MOQ:1 pcs

Warranty Time:1 year

Certificates:ISO9001

Heidenhain elevator encoder ERN1387 204862S14-70

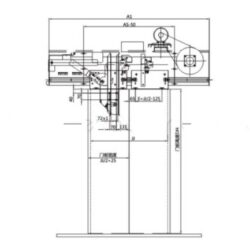

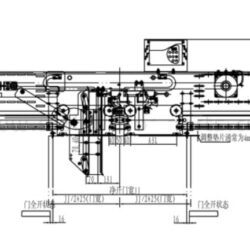

Rotary encoders with integral bearings for elevator technology

• Simple installation

• Rigid shaft coupling

• Plane-surface coupling for large mounting tolerances

• Uniform dimensions for Various e…