KONE elevator traction machine

KONE elevator traction machine MX10 KM811506G01

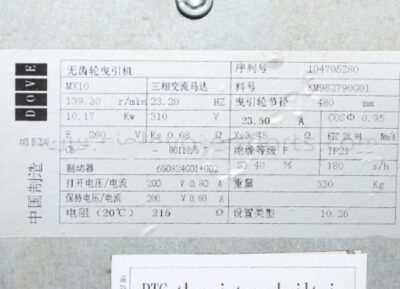

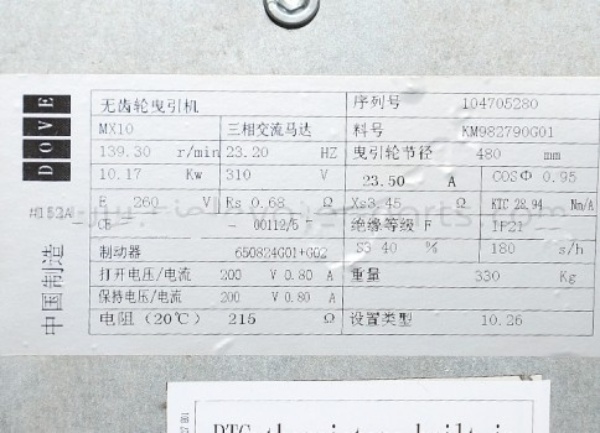

Model:MX10 KM811506G01

Brand:KONE

MOQ:1 pcs

Warranty Time:1 year

Certificates:ISO9001

KONE elevator traction machine MX10 KM811506G01

Model No.: KONE MX10 Gearless KM811506G01

Type: Driving System

Roping 2:1

Capacity 1000-1150kg

Speed 1.0-2.5m/s

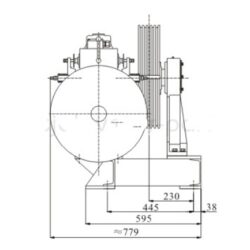

Sheave Diameter 480mm

Power 5.7-14.6kW…